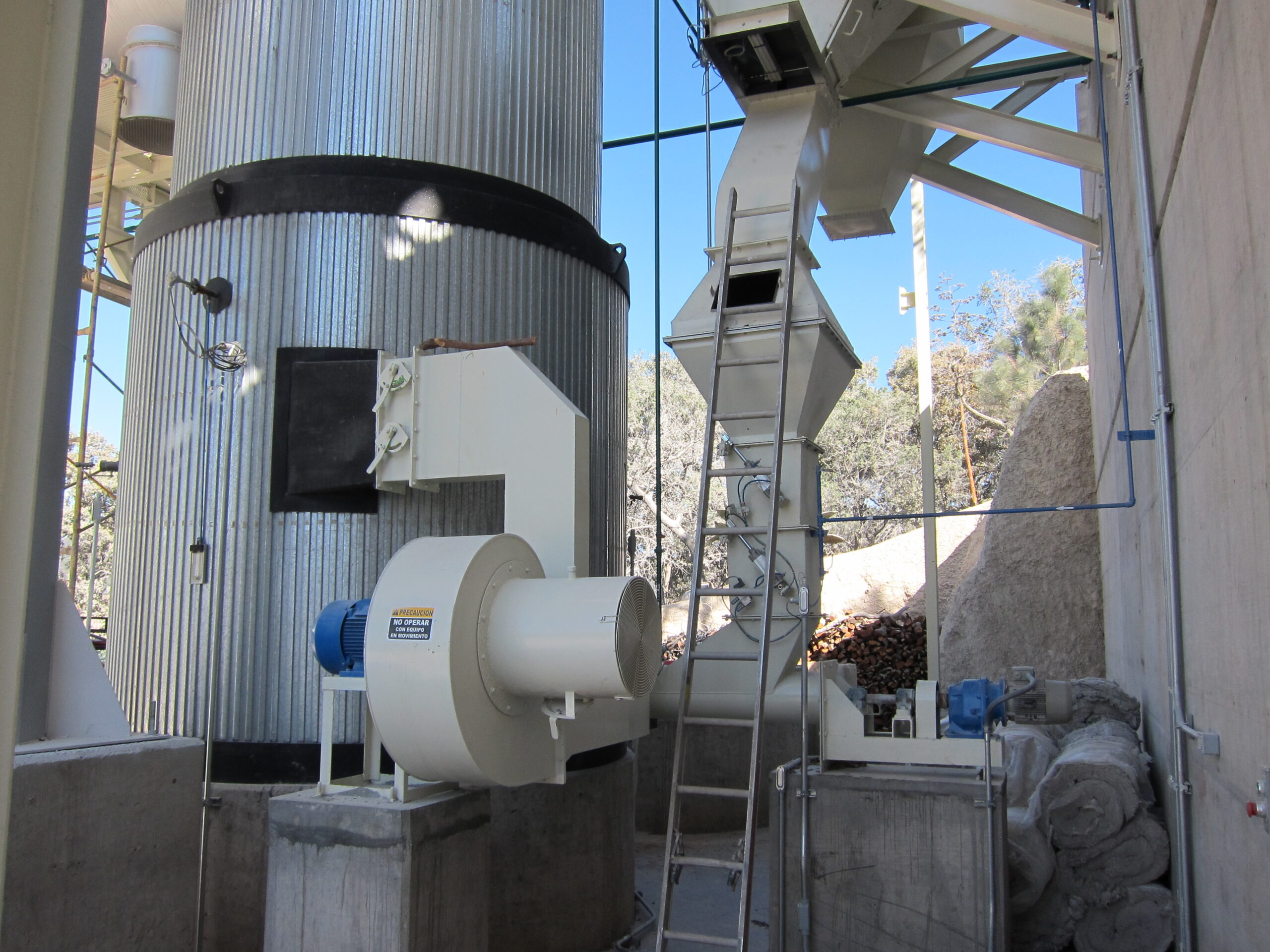

INNERGY rotary dryers are advanced solutions designed for the evaporation and drying of materials in a wide range of industries. These equipment are capable of handling evaporation capacities that vary from 500 to 10,000 liters per hour, adapting to different production needs and industrial processes. Rotary dryers can use both residual energy generated by other processes and direct or indirect combustion gases, thus optimizing energy efficiency and reducing operating costs.

- Evaporation capacity from 500 to 10,000 liters per hour.

- Suitable for various industrial applications and types of materials.

- Utilization of residual energy from the power generation process.

- Possibility of using direct or indirect combustion gases for drying.

- Manufactured with high quality materials for long life and resistance to adverse conditions.

- Rotary system ensures uniform and efficient drying.

- Suitable for drying various materials, including biomass, chemicals, food, minerals and more.

- Customizable configurations according to specific customer requirements.

- Modular design for easy installation and integration into existing processes.

- Advanced control systems for simple and automated operation.

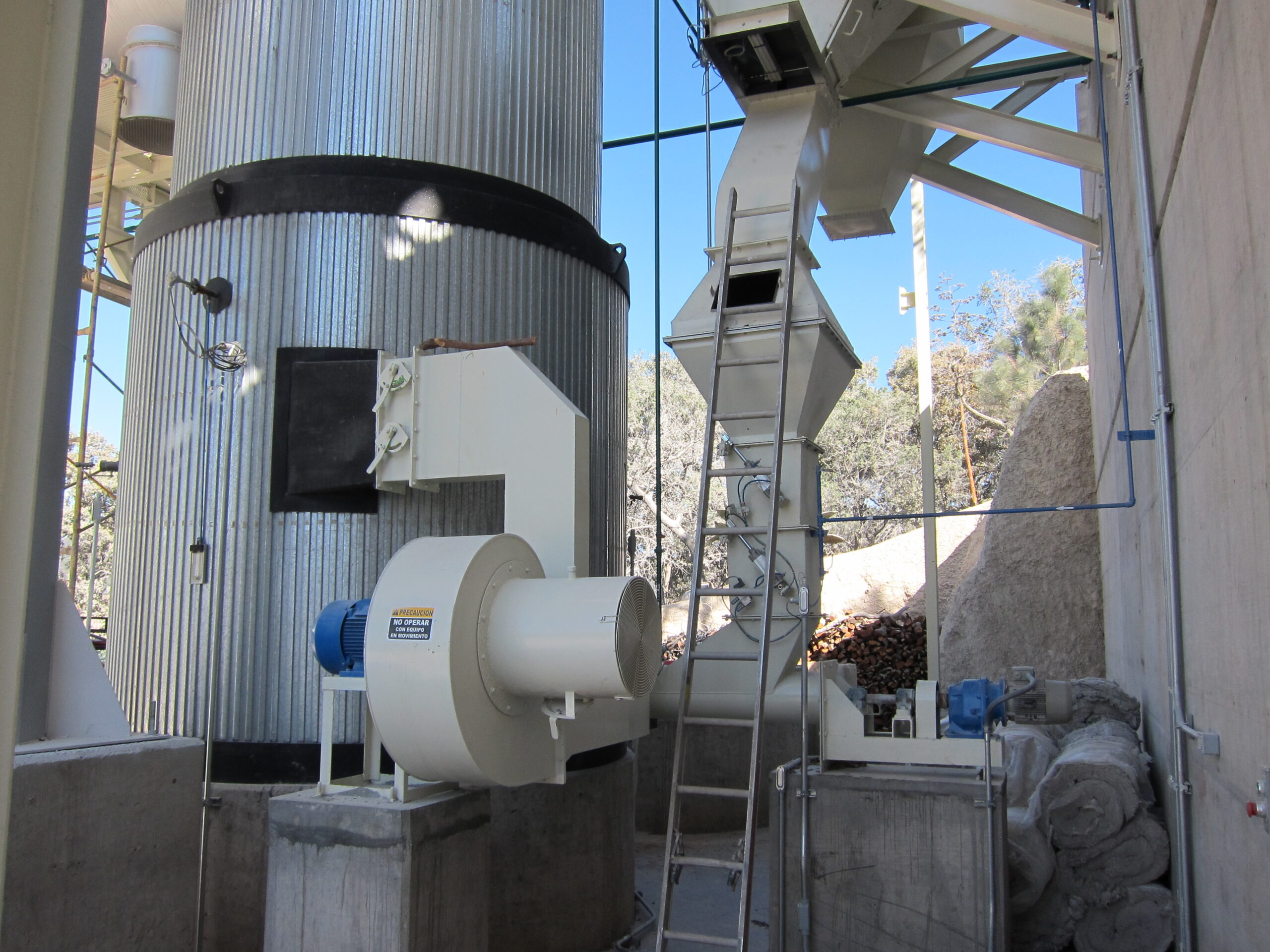

INNERGY rotary dryers are advanced solutions designed for the evaporation and drying of materials in a wide range of industries. These equipment are capable of handling evaporation capacities that vary from 500 to 10,000 liters per hour, adapting to different production needs and industrial processes. Rotary dryers can use both residual energy generated by other processes and direct or indirect combustion gases, thus optimizing energy efficiency and reducing operating costs.

- Evaporation capacity from 500 to 10,000 liters per hour.

- Suitable for various industrial applications and types of materials.

- Utilization of residual energy from the power generation process.

- Possibility of using direct or indirect combustion gases for drying.

- Manufactured with high quality materials for long life and resistance to adverse conditions.

- Rotary system ensures uniform and efficient drying.

- Suitable for drying various materials, including biomass, chemicals, food, minerals and more.

- Customizable configurations according to specific customer requirements.

- Modular design for easy installation and integration into existing processes.

- Advanced control systems for simple and automated operation.